3D CAD visualization redefines quality assurance

July 15, 2025

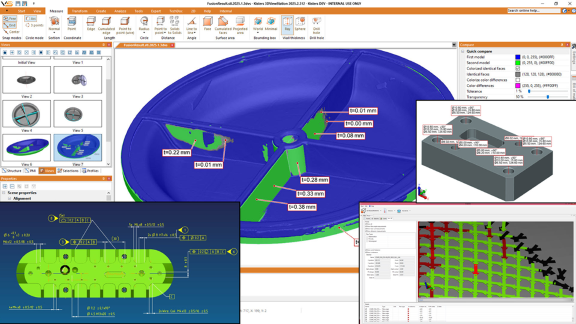

In modern manufacturing, quality and success result from precise planning, comprehensive documentation, and efficient tools. KISTERS 3DViewStation equips companies with a powerful visualization and analysis tool that has established itself as an indispensable component in the quality assurance of 3D CAD data. From prototyping to goods receipt, the software streamlines precise, system-independent inspection of complex CAD models.

Speed and precision for the highest demands

In production, every second counts. And in quality assurance, every deviation costs. 3DViewStation loads even the largest, most complex assemblies in seconds to support QA specialists and their direct inspection of digital models – without relying on original CAD systems. Supporting 60+ formats such as CATIA, NX, SolidWorks, JT, STEP and more, this platform enables universal visualization for all CAD data.

The software provides important insights into component quality. It features precise measurement functions, section analyses, and wall thickness checks. The comparison function enables analysis of different versions of a component; in addition, it can compare the 3D CAD model with 3D scans of the produced component – a key factor in change management and production. To that end, the “best fit” function minimizes the effort required to ideally position the CAD model and 3D scan before comparison can be conducted.

“In quality assurance, the ability to assess complex geometries quickly and reliably is important. That’s exactly what 3DViewStation was developed for,” explains Craig Impastato, BU ITX sales director at KISTERS North America.

Streamline processes from design review to initial sample inspection

3DViewStation digitally supports the entire quality throughout your manufacturing process.

- Design and change comparisons

Compare different CAD versions to confirm changes are implemented correctly. - Tolerance inspection & dimensioning

Check geometries for dimensional accuracy, approving dimensions directly in the model. Identify deviations by placing special symbols, attaching flags/balloons (3D annotations) or coloring — either automatically or interactively / manually - Collision detection

Detect potential collisions or installation space violations before incurring costly errors. - Documentation & communication

Easily create test reports and communicate concerns using 3D ballooning / 3D annotations, 3D markups, screenshots, or HTML integration. - Automated inspection processes

Use batch functions to automate recurring inspections, for example in goods receipts or supplier evaluations.

3DViewStation supports compliant and traceable quality assurance, especially in regulated industries such as automotive, aerospace, or biomedical technologies.

Elevate collaboration and partnerships

Viewing models on workstations, mobile device web browsers, or virtual reality (VR) enables teams to experience efficiency, productive collaboration across multiple locations. Quality assurance becomes elevated to a virtuous digitally cycle with more timely participation.

Consider this customer success: An international supplier uses 3DViewStation in goods receiving to compare delivered CAD data with approved models. The fully automated process doesn’t require manually opening of models in the original CAD system. It saves time, prevents errors, and improves supplier evaluations.

Integrate to enhance existing IT networks

3DViewStation can be fully integrated into existing engineering IT structures such as PLM systems, PDM platforms, or QM databases. A flexible API powers customized use cases. “3DViewStation brings precision and speed to quality assurance – adding real value in the age of digital twins and Industry 4.0,” says Impastato.