3DViewStation supports Model-Based Definition (MBD)

November 8, 2022

Product quality improves with completely digital process, no drawings

Conventional 2D drawings are still common in manufacturing processes. However, replacing drawings with a completely digital process known as model-based definition (MBD) can save time and costs from production delays.

Consistent reuse of computer-aided design (CAD) data also improves product quality.

When suppliers prepare quotes, drawings must be read carefully to estimate production effort and calculate the most competitive price feasible. Manufacturing cost estimation is further complicated by highly complex products, and poor process documentation and confusion can add extra costs and delays.

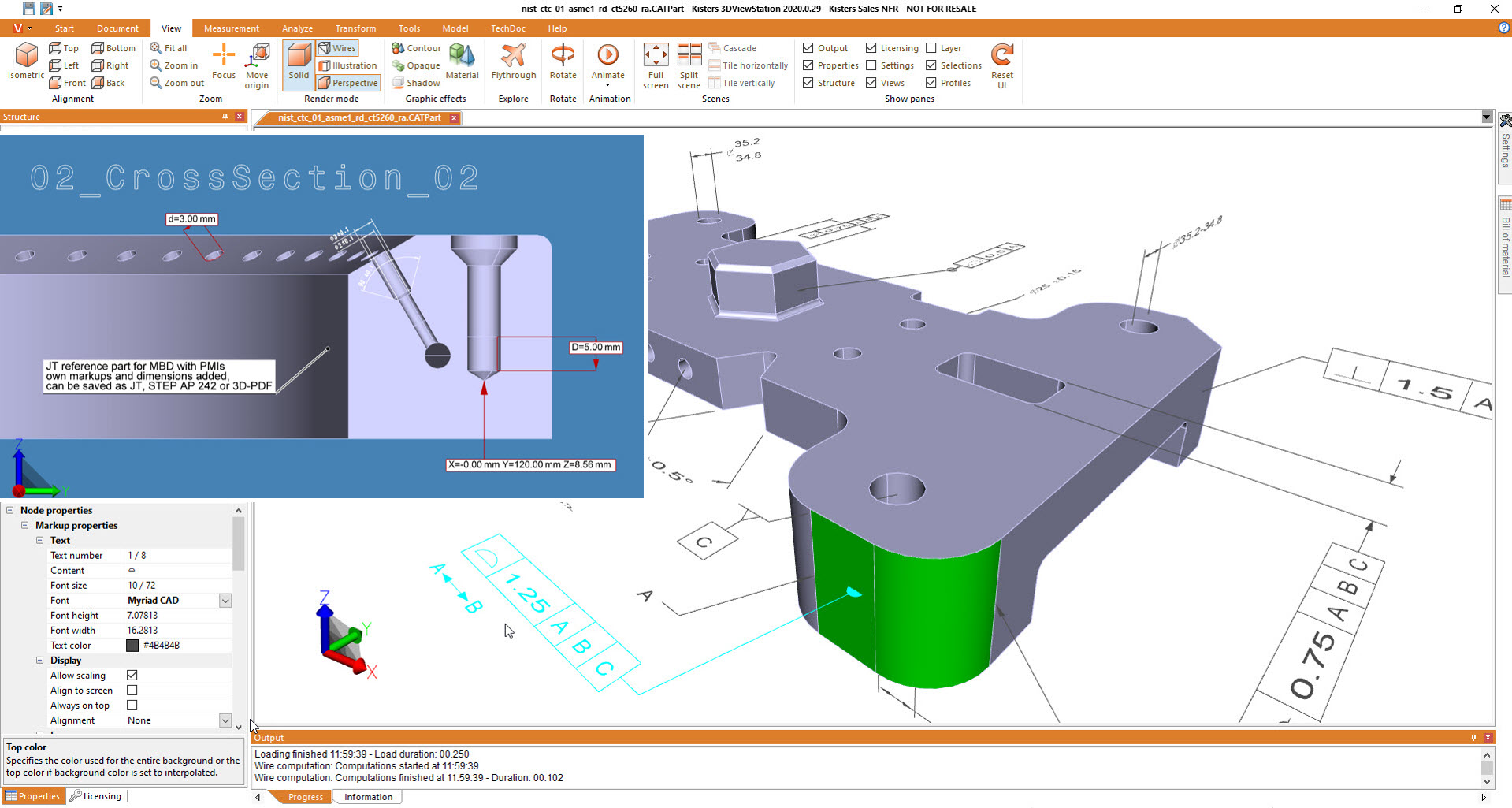

3DViewStation software supports model-based definition (MBD) processes. By storing all production-relevant product information in the digital 3D model from the beginning, MBD makes the 3D CAD model the source authority or “3D master.”

Then 3DViewStation users can quickly and easily annotate 3D CAD models and view other annotations on the source file. The immediate access to information during all processes downstream of design – from sales and work preparation to quality assurance – empowers suppliers to focus on resolving concerns or problems.

“A good 3D viewer can semantically read and display 3D annotations in the CAD model,” explained Jim Eardly, U.S. Sales Director, “3DViewStation clearly and efficiently displays these comments, parts lists, – in addition to renderings, exploded views, and surface information like tolerance zones.”

KISTERS 2D / 3D CAD viewer also supports the reading and annotation or markup of product manufacturing information (PMI) from numerous sources such as Catia, Creo, NX, JT, STEP as well as 2D PDFs with attached JT. Markups such as lines, texts or position number graphics can be added and saved again as PMI, for easy comparison of different revision levels in 3DViewStation.

The intuitive use and affordability of the software increases collaborative manufacturing, which has been limited to product engineers due to expensive CAD software licensing.

Eardly noted, “The MBD approach and use of 3DViewStation can accelerate manufacturing of complex products, improve accuracy while reducing costs.”

Read the latest 3DViewStation developments in detail at www.3dviewstation.com/news/blog.html